Denver Bed Type Vertical Milling Machine DM - 4V / 4VS / 5V / 5VS

1. Casting made of high FC-30 high quality for extra rigidity.

2. Spindle of SCM-21 alloy steel & precision ground, with class P4 bearings to ensure best

accuracy on high speed running.

* Spindle Motor of DM-5VS with AC 5HP magnetic brake, it may stop - running at the

twinkling.

3. Milling head with balance weight for smooth elevating movement.

4. Bed & column as box type, long square sliding ways, & wider base for turning stability.

5. Square slide way have been ultra-frequency treated & precision ground, XYZ-axes with

Turcite-B.

6. XYZ-axes with ball screw to smooth in precision cutting.

7. XYZ-axes with brake Motor rapid feeding, controlled by inverter, for automatic & vari speed

with high accuracy position.

8. All sliding way with automatic lubrication.

[+] Show More

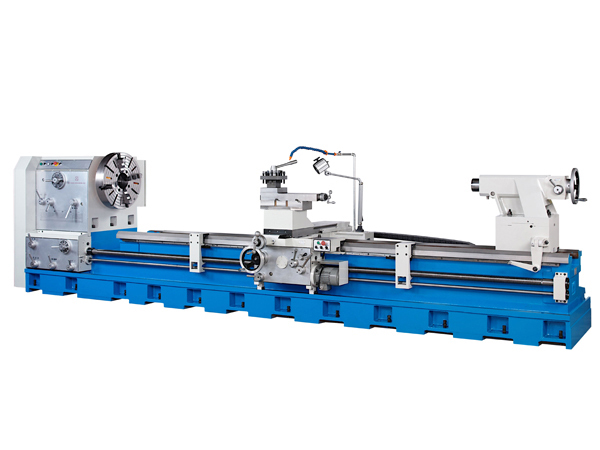

Denver Heavy Duty Lathe HL-960, 1120, 1220~1620 x 1500, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 9000, 10000

SPINDLE BORE: 9", 10",12", 15", 20"

- only fit to swing over bed over 1120mm

BED WIDTH: 24" (610mm)

*Standard accessories shall be subject to the quotation.

It is suitable for turning and cutting of large work piece and steel rod materials for heavy industries like oil pipe network, aerospace and heavy-duty shaft processing.

1. Base

(1) One piece casting work with reinforced inner structure, extra 3rd support to be suitable

for processing of large work piece and enhanced heavy-duty cutting ability.

(2) The gap part base special with reinforced structure, it is no influence on cutting stability

to break the gap for necessary.

2. Spindle & Headstock

(1) Bore 9", 10",12", 15", 20" (only fit to swing over bed over 1120mm)

(2) Turbine speed change, turbine speed change mechanism with on easy speed jumping and

three-point support for the box.

(3) Fitted with adjustable, electromagnetic brake for easy braking adjustment according to

different work piece materials and speed.

(4) Gear and shaft are made of super alloy material with bearings to offer durable cutting

and low production noise.

(5) Sealed oil bath lubrication system with enforced oil supply by mechanical pump to

achieve better lubrication effects.

3. Gear box

Adopt quick-change universal metric/inch gearbox for inch, metric, DP, MP, threading and multiple Threads, all function is reached without any change gear, wide and complete range of Threads and operating easily to improve production efficiency.

4. Apron

Equipped with rapid feeding, rapid transmission, forward / reverse movement, and safety device matched with sealed oil bath auto-lubricating system.

5. Saddle

Anti-friction processed surface with regular oil injection, lubricated and friction endurable.

6. Tailstock

Two stage feeding device, swing arm movement to have smooth and labor saving operation.

7. Electrical control

20HP / 30HP Motor, 2 stage safety start-up device and overloading power cut system.

8. Casting

FC-30 steel are used for main structures like base, spindle, saddle and Tailstock, which are annealed and have no deformation.

9. Processing

Base, spindle, saddle, dovetail slot surface of cross slide, top slide and tailstock quill are high frequency treated, precision ground for extended service life.

[+] Show More

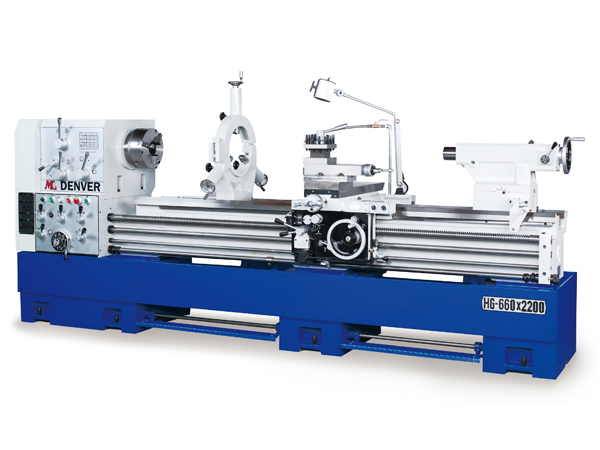

Denver Heavy Duty Precision & Powerful Lathe HG-660 / 760 / 800 / 840 X 1200, 1700, 2200, 3200, 4200, 5000

This machine is suitable for heavy cutting, easy operation, high tenacity, stability and heavy workload, which are good for heavy turning of mold, gear, wheel, shaft, central spindle etc.

1. Base

Designed for heavy duty cutting; this base is made of high quality Mechanite casting and design of rigid construction increase the loading capacity and processing stability.

2. Compound rest

Adopt 4-point tightened the rest to ensure the stability of compound rest. Wider tool post and top slide are induction hardened and ground precisely to promise a long life.

3. Spindle & headstock

12-step speed change, the spindle is supported by three points with bearings. G ears and spindle are made of high quality alloy carbon treated, spindle bore 80mm or 105mm, precision ground to acquire much superior hardness and tenacity.

4. Gear box

(1) Adopt metric / inch gearbox for inch, metric, DP, MP, threading and multiple threads, all

function is reached without any change gear, wide and complete range of threads and

operating easily to improve production efficiency.

(2) Two T.P.I per inch is available for inch threading, which provide wider threading range

than other similar specification of lathe and more convenient for operating.

5. Carriage & saddle

The contacting surfaces with bedways are pasted with Turcite-B. The slot surface of dovetail slide way has been ultra-frequency heat treated (induction hardened and ground) to promise a long service life.

6. Apron

Enforced oil feeding device, which ensure the slide ways with proper lubricating, effectively keep high accuracy turning, reduce the wearing of slide ways. Provide safety device to prevent the collision while turning from danger.

7. Cross slide screw

Two point support and suitable for heavy duty turning.

8. Tailstock

Two steps fixed device for Tailstock increase the capacity of heavy duty turning and drilling stability.

Two steps feeding device for easy operation.

[+] Show More

Denver High Speed Variable-Speed Lathe LV-460 / 560 X 500, 750, 1000 , 1500 , 2000

Main Features / Variable spindle, auto speed change

Speed adjustable, easy operation, economy.

FEATURES

1. One piece Meehamite casting machine base.

2. Metric & inch gear box with full range of inch, metric, DP, MP threading and multiple

threads, all function is reached without change gear.

3. Apron enforced oil supply with safety device is used to avoid collision.

4. Bed ways & surface of compound rest have been ultra-frequency heat treated & ground to

provide a longer life.

5. Cross way feeding guides screw: 2 points support for heavy cutting.

6. Length safety foot brake.

7. Dynamically balanced alloy spindle is adopted 3 points of bearing support.

8. The gears in headstock and spindle are hardened & precision ground.

[+] Show More

Denver Vertical Horizontal Turret Milling Machine DM - 186 VH / VSH Series

1. The body casting is made of high quality meechanite.

2. Spindle is made of SCM-4 shaft chrome-molybdenum steel, heat treatment after carburing,

and precision ground.

3. Turcite-B are coated on XY-axes.

4. Work table & sliderways of XYZ-axes are hardened & ground.

5. Square slideway on YZ-axes.

6. Direct-shift "Hight / Low" switch.

7. PCB phosphor bronze leadscrew nut.

[+] Show More

Denver Vertical Turret Milling Machine DM - 150, 160, 180, 186V / VS Series

1. The body casting is made of high quality Meechanite.

2. Spindle is made of SCM-4 shaft chrome-molybdenum steel, heat treatment after carburizing,

and precision ground.

3. Turcite-B are coated on XY-axes.

4. Work table & slide ways of XYZ-axes are hardened & ground.

5. Square slideway on Y-axis.

6. Direct-shift "High / Low" switch.

7. The slideway of Z-axis is hardened & ground for DM-180 & DM-186.

8. Square slideway on Z-axis for DM-180 & DM-186.

[+] Show More

Eastar 1-Light Duty Shear HS-12/16/20/30

Hand Rod & Plate Shear

Sheet:4~6m/m

Blade length:120~30m/m

[+] Show More

Eastar Bending Machine

Bending Capacity

Angle Iron(L)mm-150x150x15

Flat iron(-) mm-150x30

Iron Pipe(o)mm216x8

Motor HP-20

Dia of the standard rolls(mm)-500

Shaft Dia Top/Lower(mm)-180,180

Rolling speed-(3~7)

Weight kg-10,000

[+] Show More

Eastar Heavy Hydraulic Shear

LB-1010H

Heavy/Hydraulic Shear

Shear Cap.:3.5x2500~3100mm

Stroke:15~18mm

[+] Show More